Graphite Felt - Best Insulation Material for Industrial Furnaces

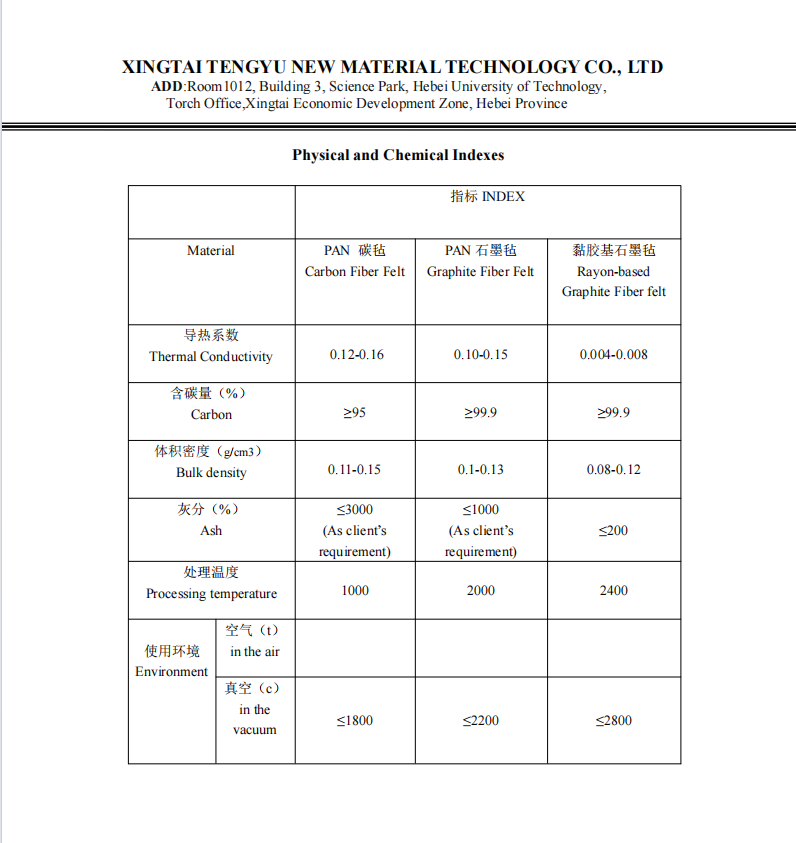

Graphite felt is usually divided into PAN carbon felt, PAN graphite felt, and viscose-based graphite felt, which are widely used in high-temperature vacuum furnaces, Intert gas furnaces, redox flow batteries, etc. Among them, PAN graphite felt is often used in the vacuum aluminum plating industry.

Graphite felt, also known as graphite fiber felt, is mainly used as thermal insulation refractory materials for various industrial furnaces such as single crystal furnaces, carbonization furnaces, quartz furnaces, vacuum furnaces, heat balance reaction furnaces, heat treatment furnaces, sintering furnaces, etc. Welding furnaces and high-pressure furnaces in metallurgy, machinery, chemical and other industries. It is also used as a filter material for high-purity corrosive chemical reagents. The carbon content of graphite felt is above 99%, which is higher than that of carbon felt. Under non-oxidizing atmosphere conditions, its operating temperature can reach above 2000℃. It has the characteristics of high tensile strength, high tensile modulus, low density, high temperature resistance, ablation resistance, corrosion resistance, high electrical and thermal conductivity, low thermal expansion, and self-lubrication. It is combined with graphite composite plates and graphite special-shaped parts to form the insulation layer of industrial furnaces.

Packaging and Delivery

Packing details: Export standard packaging

Delivery time: Within 10-15 working days after order confirmation